Our story

We have started our R&D project with the target to find a cheap and transparent alternative to glass for the food packaging: high oxygen barrier and heat resistance were the requested variables.

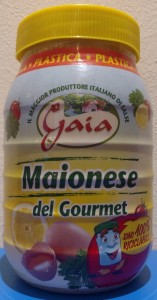

first product on the market: 1kg vase for Formec/Biffi group.

First production of a squeezable bottle (customer: Consorzio Casalasco / Kraft).

First production of single serving portion jar for fruit mustard (customer: Luigi Lazzaris & Figlio s.r.l.).

First production of milk/dairy products: a yogurt packaging created with two-stage technology.

Thanks to the success of our first join project, Kraft has also entrusted us with the production of the well-known ketchup bottle Mato Mato.

Reinforcing two-stage production for milk/dairy sector with production of bottles for fresh milk (different customers).

First License Agreement contract to bring SocoJars® technology outside Europe: signed agreement with Ozler Plastik Group to cover Turkey, Malta, Azerbaijan and North Iraq.

Boschetti Alimentare (part of the French group Valade) decided to switch from glass to SocoJars® for both their ottagonal vase and the one-seater vessel.

Tonitto Gelati launches its high-quality sorbet with a jar designed to enhance the high quality of their product.

Valdoglio is the first client in syrup business.

.

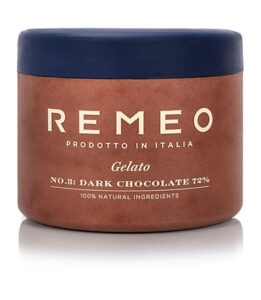

First ice cream jar 100% made with RPET (recycled PET) produced in EU for Remeo.

Socopet massively enters the world of vinegar bottles.

Socopet realize the first bottle for balsamic vinegar glaze realized with the two-stage technology.

Socopet realizes a massive shift of old and new customers, towards the use of RPET (recycled material for direct food contact): the result is that in 2021 more than 60% of production is made with at least a percentage of RPET inside.